There are several reasons to consider the importance of seismic bracing of commercial buildings including manufacturing facilities, warehouses, hotels and more. The most common international building codes including the IBC, EUROCODES, Italian NTC, require that structural components be braced properly to these requirements.

nVent CADDY Engineer and Business Development Manager in EMEA, Matteo Baleni, specializes in seismic protection and nVent CADDY’s Seismic Bracing Solutions. Read through our conversation with him about the importance of seismic bracing and what should be considered.

Design Codes and Standards

While codes and standards are more advanced in the United States, specifically states like California, there are several variations in the codes and standards used in Europe.

“Understanding the importance of seismically bracing includes what the seismic risk is, and if the building’s important systems are braced properly to stay in proper use after a seismic event,” Matteo said. “While structural elements are typically covered by standards and codes, non-structural elements are not always covered. This includes HVAC, gas, electrical, mechanical, disposal and fire protection systems.”

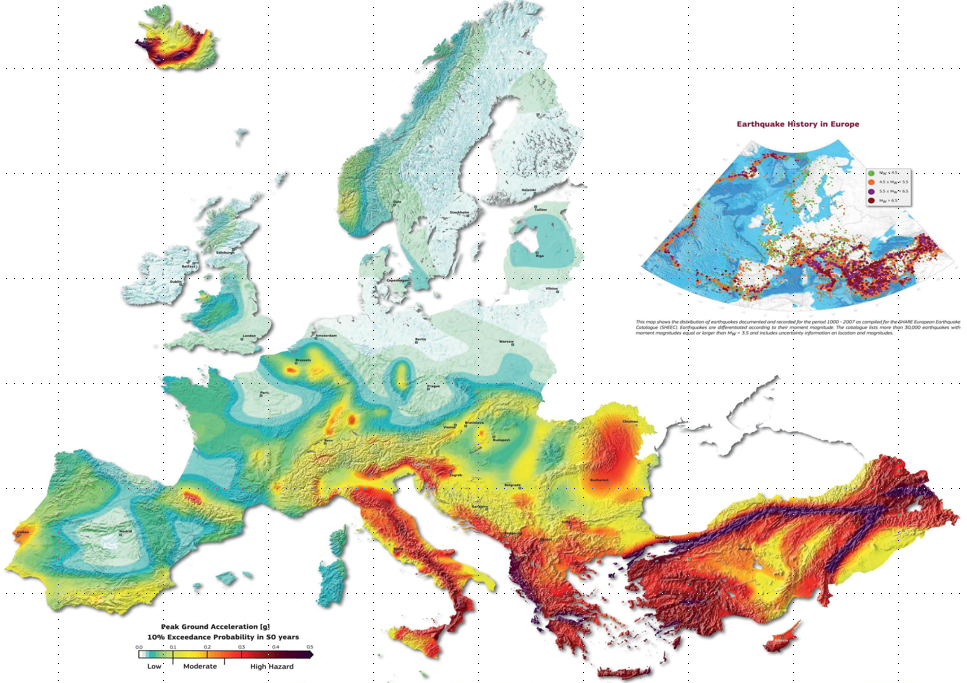

Seismicity map outlining degrees of seismic risk in Europe

Fire protection systems are life-saving systems that are important to operate safely during and after a seismic event. Matteo says it’s important to consider installing seismic bracing systems whether a job is a new build or a retrofit.

When considering which seismic bracing systems to use, products that are already compliant are the proper solution, even if they are not required at this time. As codes and standards mature in Europe, these products will be required and should become the gold standard. Not only should the products be top of the line, but an educated understanding of the standards, codes and engineering behind those products are just important.

Customized Engineering Services and Expertise/Localized Support

Not only can nVent CADDY provide reliable, innovative and easy-to-install products, but the team can assist with engineering direction and more. Matteo says the nVent CADDY engineering team specializing in seismic bracing will help with everything from working through the proper solutions for designers and contractors to not only stay on budget, but to be compliant with existing regulations.

“Not only can our team assist with product selection, but our technical expertise will help from design to install to inspection for proper installation,” he said. “We want to eliminate the confusion that can come with understanding what is required by working through what is needed and how to best design the system.”

Product Quality and Options

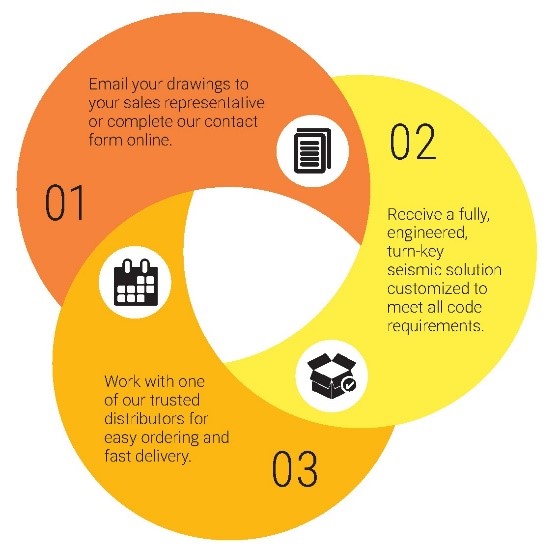

We Make Seismic Simple!

Once the team takes the time to work through the technical and design plans for the system, a bill of materials is created for the job, and high-quality nVent CADDY products are delivered.

“nVent CADDY products are easy-to-install, and we also provide resources like our calculation tool and installation handbooks to assist in installation,” says Matteo. “From rigid bracing sway braces to cable bracing products, the products can be used in a variety of jobs including fire protection, mechanical, electrical and plumbing systems. And they have gone through rigorous testing. A lot of thought and work goes into each plan.”

The recommended solutions are engineered with the breadth of product options, without having to develop a whole custom solution (which can cost much more), and each scenario is examined to ensure challenges and delays can be avoided, if possible.

“A common problem is narrow installation spaces,” he says. “In a recent job, our engineering and technology team assisted in finding a solution for very specific technical requirements. We were able to use seismic bracing in conjunction with the nVent CADDY MACROFIX product as well. We worked closely to review all of the design made by the engineer to ensure they met these requirements properly.”

Not only were the plans successfully provided, but the products were delivered with precise planning, making the job smoother for the distributor and end user as well.

Want your own success story using nVent CADDY Seismic Bracing Systems? Contact us today to get started. https://go.nvent.com/EFS-Contact-Us.html.

Matteo Baleni is the Business Development Manager in the EMEA region for nVent CADDY Seismic Protection. He received his Civil Engineering Degree (Hydraulics specialization) from Milan’s Politecnico University. Matteo has spent his entire professional life in the supporting systems business, working for companies like Hilti, Tyco, MEFA and Knauf in both Technical and Sales Engineering Departments.